Company Profile

Our History

Zhejiang Arris IMP & EXP Co., Ltd. prioritizes product quality management and strongly emphasizes environmental consciousness, becoming the first in our industry to achieve ISO9001 Quality Management System certification, ISO14001 Environmental Management System certification, and European CE certification.

As China's leader in the Wood-Plastic Composite (WPC) industry, ARRIS's WPC products have been exported to over 100 countries and regions worldwide, including the United States, United Kingdom, Russia, South Africa, Thailand, India, Germany, Spain, Finland, and Australia, earning widespread acclaim from clients. While helping customers maximize their benefits, innovative and excellent ARRIS is committed to becoming China's most professional pioneer and manufacturer of eco-friendly, energy-efficient building products through exceptional product quality, specialized technical expertise, and sincere customer service.

Our Factory

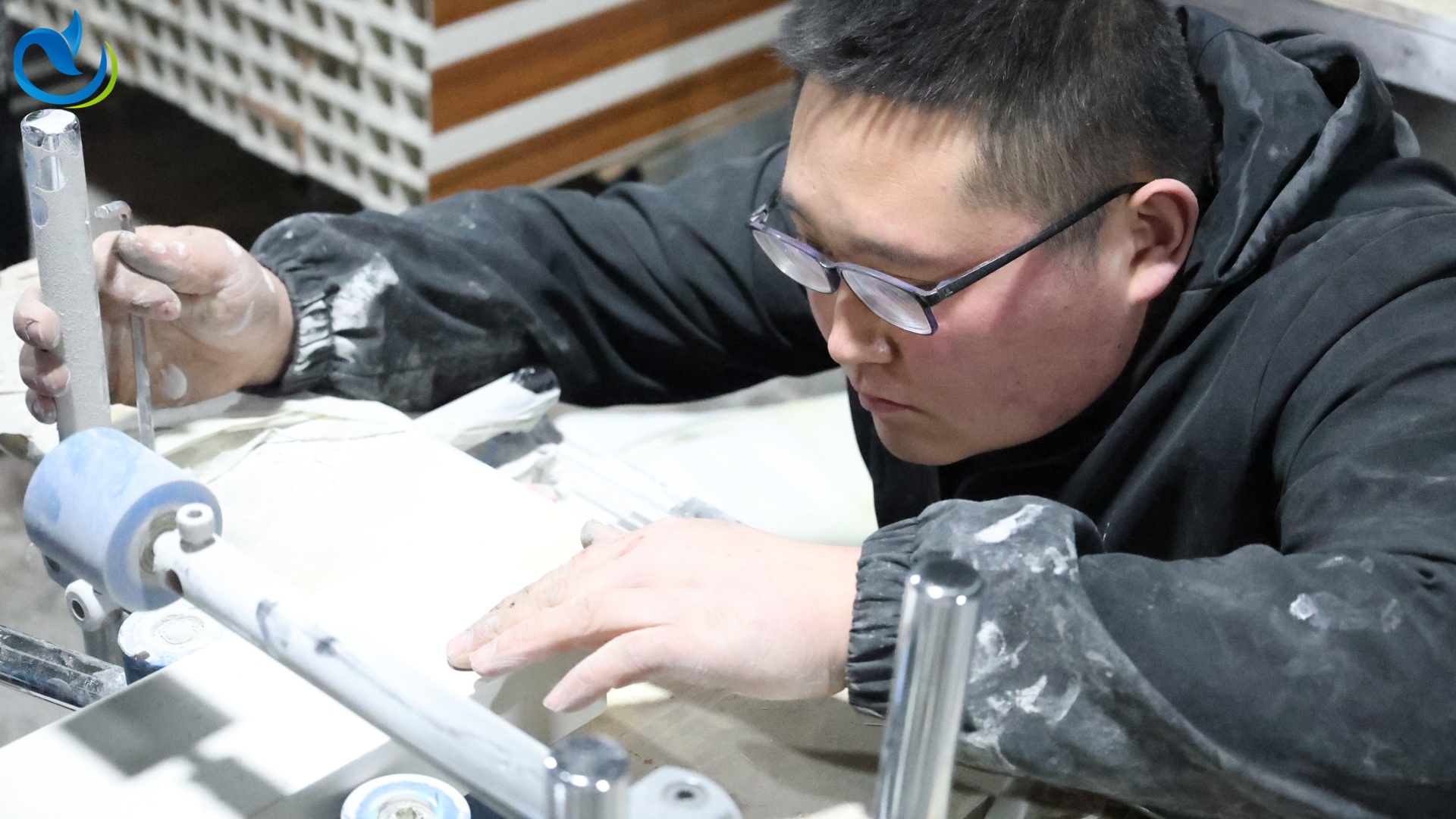

As an innovation leader in China's wood-plastic composite (WPC) industry, Zhejiang ARRIS Import & Export Co., Ltd. has established modern production bases in Zhejiang and Shandong since 2015 to deepen the business layout of environmental protection building materials, forming a dual-core manufacturing system covering the Yangtze River Delta and the Bohai Economic Circle. Relying on more than 20 years of precision manufacturing experience (the parent company was founded in 2000), the company focuses on the research and development and innovation of wood-plastic products, takes the lead in passing the ISO9001 quality management system,ISO14001 environmental management system and EU CE certification, and builds a complete industrial chain from raw material modification to finished product manufacturing.

Core advantages: Using 4-D CNC winding, automatic curing and other advanced technology, the product has the characteristics of corrosion resistance, moisture proof and flame retardant, zero formaldehyde release, suitable for outdoor landscape, interior decoration and other fields.

Production strength: Zhejiang base is equipped with German imported extrusion production line, with an annual capacity of 50,000 tons; The Shandong factory introduced AI visual inspection system to realize the digital control of the whole process from raw material ratio to surface treatment, and the product yield remained above 99.2%.

Global layout: The products are exported to more than 100 countries in Europe, America and Southeast Asia, and provide material solutions for international green buildings such as passive house projects in the United States and Germany, with exports accounting for 65% of annual sales.

Sustainable development

Practicing the environmental protection concept of "replacing wood with plastic", recycled plastics accounted for more than 70% of raw materials, and the utilization rate of waste wood reached 95%. In 2023, it was awarded the national high-tech enterprise5 and led the development of the industry standard of Wood-plastic Composite Board for Construction to promote the green upgrading of the industry.

Service system

The establishment of "R&D - production - installation" integrated service: engineering grade products 30 days delivery guarantee

Worldwide warranty and regular maintenance services.

We sincerely invite partners at home and abroad to expand the market of environmental protection building materials.

Our Service

In addition to our existing products, we can produce various products according to customers' drawings or samples. We will communicate with you in detail in the early stage. After product confirmation, we will give the customer a sample of the goods before production, and we will start production after customer confirmation. In the production process, we will strictly control product quality, and we will make compensation if there is any quality problem. The quality and efficiency of the products we provide are few and far between.Our corporate purpose is integrity-based, which is also an important reason why we are getting better and better.