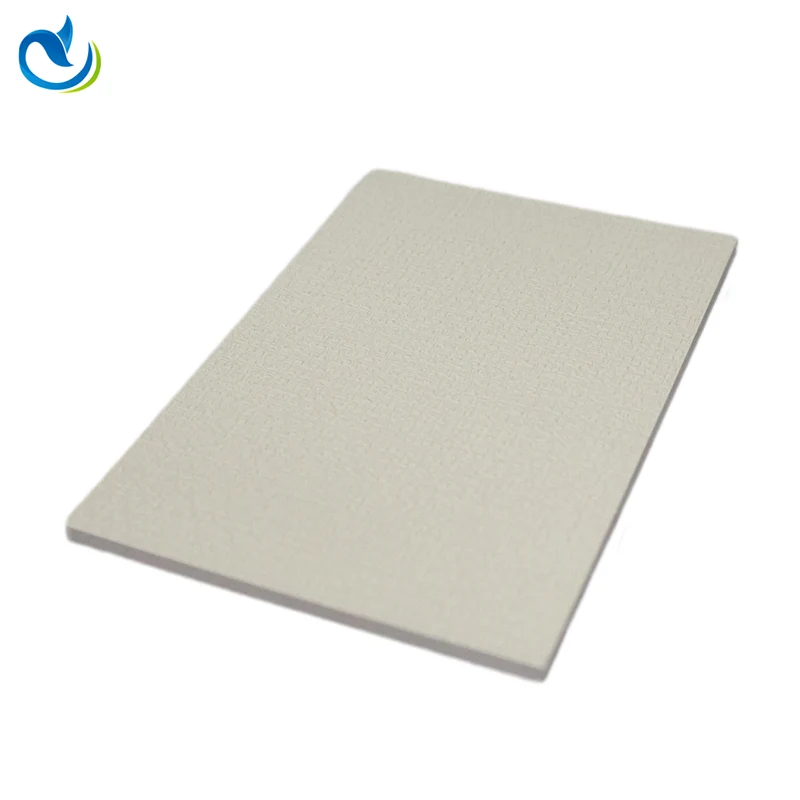

Mould Proof Carbon Crystal Wall Panel

Product advantages and performanceMaterial environmental protection: The mould proof Carbon crystal wall panel is made from environmentally friendly raw materials such as natural bamboo charcoal powder, calcium powder and food-grade PVC.The production process does not use formaldehyde containing adh......

Send Inquiry

Product advantages and performance

Material environmental protection: The mould proof Carbon crystal wall panel is made from environmentally friendly raw materials such as natural bamboo charcoal powder, calcium powder and food-grade PVC.The production process does not use formaldehyde containing adhesives, and the formaldehyde emission is ≤ 0.05mg/m ³, far superior to the national E0 level standard.The bamboo charcoal molecules inherently possess adsorption capabilities, which can degrade the free formaldehyde in the indoor environment.The paint free coating process further reduces pollution.The elderly, children, pregnant women and families can all use it with peace of mind.

Stable performance:The carbon crystal wall board is formed through a high-temperature co-extrusion process. The surface hard co-extrusion layer has a hardness of ≥ 2H, and the wear resistance rotation number is ≥ 10,000 rotations.Can resist daily scratches and heavy object impacts.The fire resistance rating reaches the B1 standard for flame-retardant materials, and it does not contribute to the spread of fire when exposed to heat.The water absorption rate is less than 0.5%, and the carbon crystal wall plate does not mold or deform during the rainy season or humid environment. It remains stable even at extreme temperatures ranging from -30 ℃ to 120 ℃.

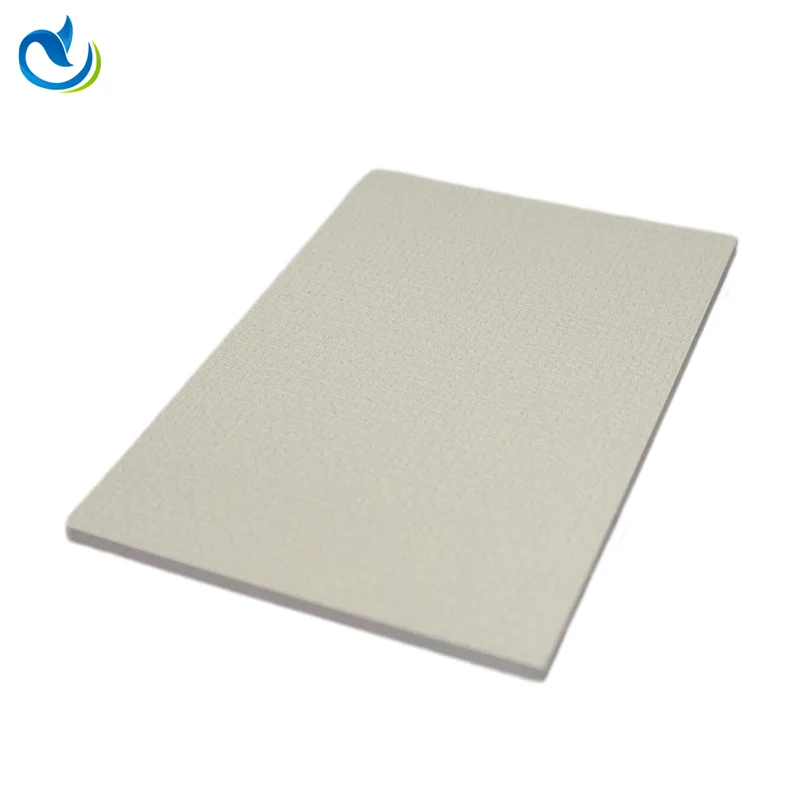

Various styles:By using PUR hot melt adhesive technology to overlay PET film, impact resistance Carbon crystal wall panels can accurately restore various textures such as wood grain, cloth grain, stone grain, and metal wire drawing.Glossiness options such as matte and soft light are available, suitable for various styles including country, minimalist, and retro.

Easy installation:With the modular design of the snap-in plates, the customization period for personalized carbon crystal plates is only 3 to 7 days.The construction efficiency is 50% higher than traditional materials, and 300 square meters of installation can be completed in a single day.

Product Parameter

|

|

Specifications |

applicable scene |

Testing Standard |

|

Basic Size |

1220*2440、1220*2600、1220*2800;customization |

Various wall surfaces, ceiling decorations, and furniture finishes |

GB/T 24137-2009 |

|

Thickness |

5~12mm |

5-6mm suitable for home decoration walls;Public places require thicker wall panels. |

GB/T 11718-2021 |

|

Physical Properties |

Impact resistance strength 15kJ/㎡;Sound insulation coefficient: 0.6 - 0.8 |

Meeting rooms and bedrooms with high sound insulation requirements;High-traffic areas |

GB/T 8624-2012 |

|

Environmental Indicators |

Formaldehyde emission≤0.05mg/m³;Recyclability rate: 85% |

Sensitive places such as residences, hospitals, kindergartens, etc |

GB 50325-2020 |

|

Functional Characteristics |

Heating type: electric energy conversion rate≥98%;Conductive type: Integrable sensor |

Heating walls; Intelligent office space |

JG/T 413-2019 |