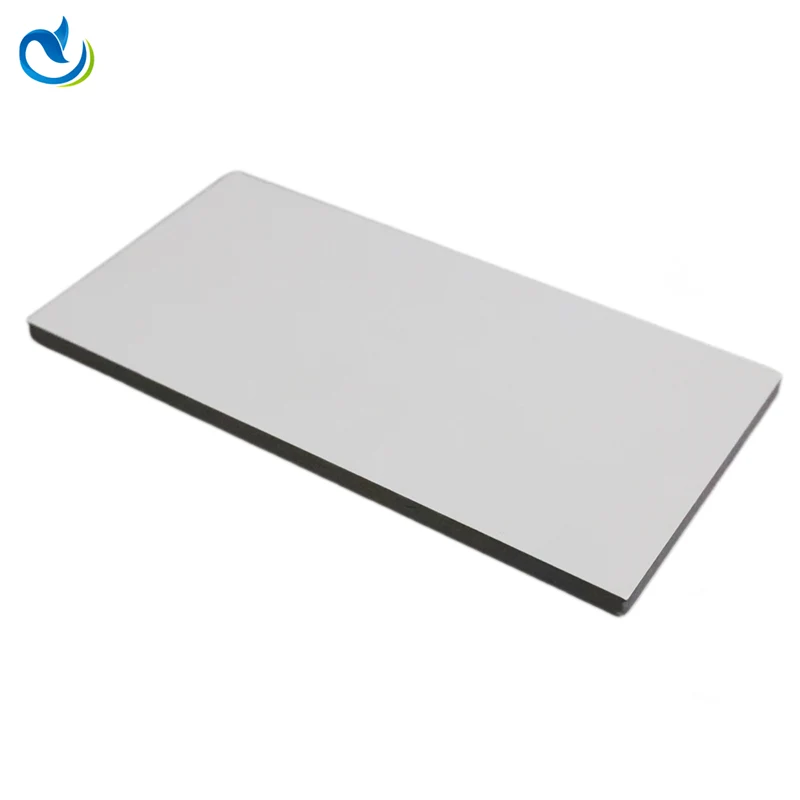

Wooden Acoustic Wall Panel

Arris supplier focuses on providing high-end Wooden Acoustic Wall Panel and overall acoustic solutions for residential buildings, commercial buildings, cultural venues, office spaces, etc. Our products not only have outstanding acoustic performance but also possess the aesthetic appeal of natural wood. They are widely used in home theaters, concert halls, meeting rooms, hotels, restaurants and other scenarios, creating quiet, comfortable and artistic spaces for customers.

Send Inquiry

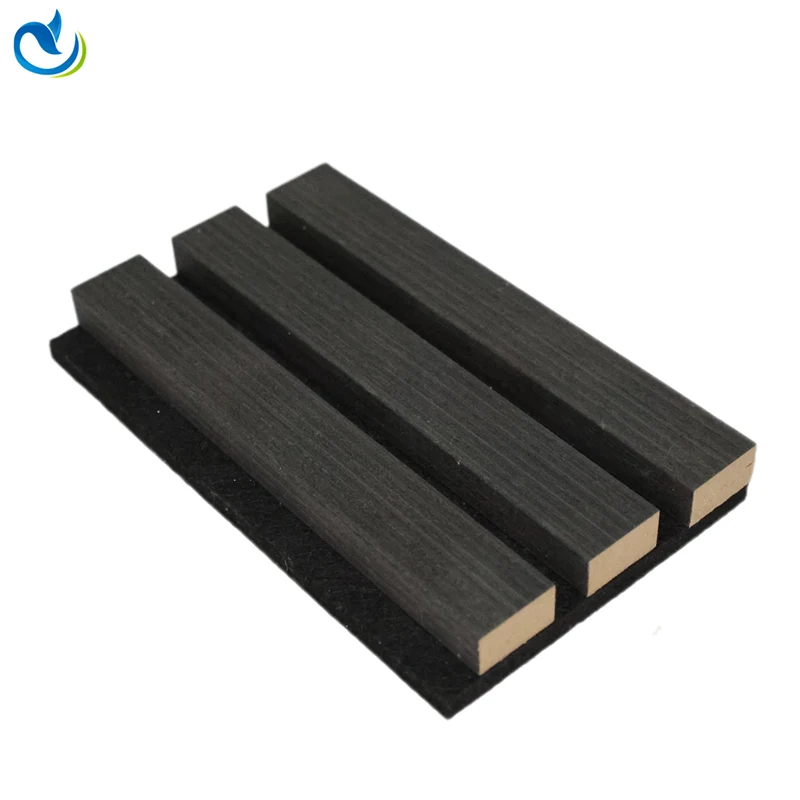

Wooden Acoustic Wall Panel is a decorative material that combines the aesthetic appeal of natural wood with efficient acoustic performance. Its manufacturing process integrates traditional woodworking techniques with modern acoustic technology.

Manufacturing Process:

1. Material Preparation

Select high-quality and environmentally friendly wood, choose high-density sound-absorbing materials as the base material, and use environmentally friendly adhesives.

2. Design and Cutting

Based on customer demands or market trends, design the size, shape and texture of the Wooden Acoustic Wall Panel.

3. Acoustic Structure Processing

Carry out perforation treatment on the surface of the wood to enhance the absorption and diffusion effects of sound waves. Glue the cut acoustic base material and the wood backboard together with an environmentally friendly adhesive to ensure firm bonding without air bubbles. Polish the edges of the wall panel.

4. Assembly and Forming

A wooden or metal frame is fabricated based on the dimensions of the wall panels to fix them and enhance the overall structural strength.

5. Surface Treatment

Perform fine sanding on the surface of the Wooden Acoustic Wall Panel to ensure smoothness without burrs.

According to the requirements, apply coating treatment to the wall panels. Options include varnish, wood wax oil or colorants to enhance the texture and luster of the wood.

6. Quality Inspection

Test the sound absorption coefficient and sound insulation effect of the wall panels, check if Wooden Acoustic Wall Panels are any flaws on the surface of the wall panels, simulate high humidity and high temperature environments, and test the stability and durability of the wall panels.

7. Packaging and Transportation

Protect the wall panels with moisture-proof and shock-proof packaging materials to ensure Wooden Acoustic Wall Panels are not damaged during transportation. Arrange logistics according to customer requirements to guarantee the safe delivery of the products.